Leading Filling Machine Supplier for Efficient Packaging Solutions

Introduction to Filling Machines

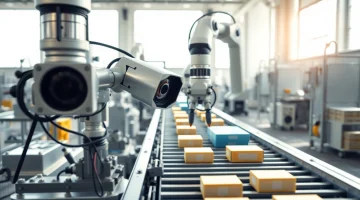

In the world of manufacturing and production, filling machines play a crucial role, enabling businesses to efficiently package their products. These machines are vital across various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, streamlining the packaging process and ensuring consistency in the quantity filled. As a prominent Filling Machine Supplier, understanding the intricacies of filling machines can empower businesses to make informed decisions about their packaging needs.

What is a Filling Machine?

A filling machine is a type of equipment used to dispense a predetermined volume or weight of liquid, granule, powder, or solid into a container. They are pivotal in ensuring that products are packaged accurately and efficiently, catering to various sectors ranging from food production to pharmaceutical manufacturing. By utilizing specialized mechanisms, filling machines can maintain hygiene standards, adhere to regulatory requirements, and enhance overall productivity.

Different Types of Filling Machines

Filling machines come in various configurations and types, each designed to meet specific manufacturing needs. The main types include:

- Manual Filling Machines: These require human intervention to fill containers and are generally used for low-volume production.

- Semi-Automatic Filling Machines: Operated with some manual control, these machines increase efficiency and reduce labor costs while still requiring some human oversight.

- Fully Automatic Filling Machines: These machines operate entirely on their own, making them ideal for high-volume production settings. They typically include advanced technology that monitors and controls the filling process.

- Piston Filling Machines: Popular for viscous liquids, these machines utilize pistons to deliver precise amounts of product, ensuring accuracy in each container.

- Pump Filling Machines: Best for thin liquids, these machines utilize pumps to fill containers with speed and efficiency.

- Gravity Filling Machines: Using gravity to fill containers, these are best suited for low-viscosity liquids.

- Vacuum Filling Machines: These machines remove air from the container to preserve product quality, particularly in the food and beverage sector.

Applications of Filling Machines

Filling machines serve various applications across multiple industries:

- Food and Beverage Industry: From juices to sauces and carbonated drinks, filling machines ensure accurate servings while minimizing spills and contamination.

- Pharmaceutical Sector: They are essential for distributing liquids and powder formulations, ensuring medications are dosed accurately for efficacy and safety.

- Cosmetics and Personal Care Products: Filling machines are also used for lotions, creams, and perfumes, requiring precision to maintain product integrity.

- Chemicals: Industrial chemicals often require specialized filling machines to manage hazardous materials safely and efficiently.

Choosing the Right Filling Machine Supplier

Selecting the right filling machine supplier is a critical decision that can significantly impact production efficiency and product quality. Here are key considerations to guide your choice:

Evaluating Supplier Expertise

Assessing a supplier’s expertise in filling technology is essential. Look for suppliers with a proven track record in your industry, as they are more likely to offer machines that cater to your specific needs. Examine their history, types of machines they provide, and the ranges of products they support. Consider reaching out to existing clients for testimonials regarding the supplier’s performance and reliability.

Quality Certification and Standards

Quality certifications such as ISO 9001 can assure you of the supplier’s commitment to maintaining industry standards. Suppliers should comply with relevant regulatory requirements related to safety, hygiene, and operational efficiency, particularly in industries such as food and pharmaceuticals. Request documentation to verify that their machines meet these standards and protocols.

Customer Support and Service

Post-purchase support is a crucial aspect to consider when selecting a supplier. A reliable filling machine supplier should offer comprehensive services, including installation, training, and ongoing maintenance. Evaluate their customer service track record, availability of technical assistance, and access to replacement parts. A responsive support team can minimize downtime and ensure your equipment stays operational.

Benefits of Using Automated Filling Machines

The integration of automated filling machines can yield significant benefits for manufacturing businesses, enhancing efficiency and effectiveness throughout the production line. Some notable advantages include:

Increased Efficiency and Productivity

Automated filling machines drastically reduce the time taken to fill containers, which is especially beneficial in high-demand settings. With minimal human intervention, these machines can operate continuously, increasing production rates and allowing businesses to meet larger volumes of orders promptly.

Precision and Accuracy in Filling

With advanced technology, automated filling machines offer heightened accuracy that manual processes cannot match. This precision minimizes product wastage and ensures that each container is filled to the correct volume, which is vital for compliance in industries like pharmaceuticals and food production.

Cost Savings in the Long Term

Investing in automated filling solutions can lead to significant cost savings over time. Beyond the reduction in labor costs, these machines decrease material wastage, ensuring greater efficiency in operations. While the upfront costs may be higher, the long-term benefits often justify the initial investment.

Innovations in Filling Machine Technology

The evolution of filling machines is marked by technological innovations that enhance their functionality. Staying informed about these trends is essential for businesses aiming to optimize their packaging processes. Notable innovations include:

Smart Technology Integration

Current filling machines increasingly incorporate smart technology, enabling real-time monitoring and data collection. These innovations allow businesses to track production efficiency, detect inconsistencies, and optimize workflows through actionable insights. Features such as IoT integration facilitate predictive maintenance, reducing unplanned downtimes.

Eco-Friendly Solutions in Manufacturing

As sustainability becomes a focal point in manufacturing, many suppliers are developing eco-friendly filling machine solutions. These machines are designed to minimize energy consumption, reduce waste, and utilize sustainable materials in their construction. Manufacturers are also adapting to changing consumer preferences for eco-conscious packaging.

Future Trends in Filling Machines

Industry experts predict several future trends in filling machine technology, including:

- Increased Customization: Tailored solutions that cater to unique manufacturing processes will become more prevalent, allowing businesses to maximize output.

- Enhanced Automation: Future machines will likely integrate AI and machine learning techniques to further streamline operations and increase adaptability in production lines.

- Advanced Cleaning and Safety Features: Innovations in hygiene technology will address increasing health regulations, particularly in food and pharmaceutical industries.

Conclusion: Partnering with a Reliable Filling Machine Supplier

In conclusion, partnering with a reliable filling machine supplier can profoundly impact the packaging efficiency of your business. As you evaluate potential suppliers, consider their expertise, quality certifications, customer support, and technological advancements. Implementing automated filling solutions not only enhances efficiency and accuracy but also positions your business to adapt to future market demands.

Key Takeaways for Businesses

To summarize:

- Filling machines are essential to achieving efficient packaging across various industries.

- Choosing the right supplier is critical; consider their expertise and support services.

- Automation significantly enhances productivity, precision, and cost-efficiency.

Getting Started with Your Supplier

To embark on your journey towards optimizing your filling processes, start by conducting thorough research on potential suppliers. Compile a list of questions regarding their products, services, and support systems. Arrange consultations to discuss your specific requirements, ensuring alignment with your operational goals.

Resources and Further Reading

For additional insights, consider exploring industry-specific forums, webinars, and publications. Engaging with peer discussions can provide valuable perspectives on the latest trends and technologies in filling machine solutions.